FREEDOM®AI Platform.

The Ultimate Platform for Operational Excellence

- Any Industry

- Any Process

- Anywhere

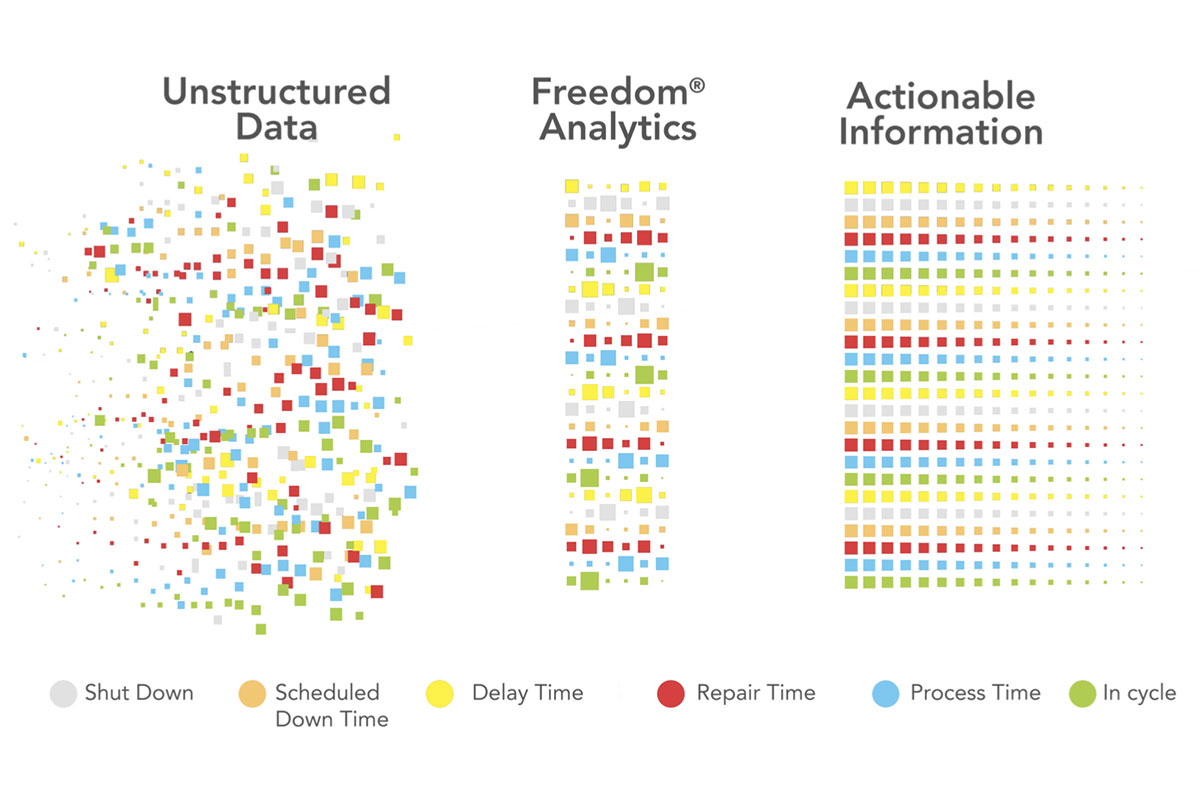

Unleash the Power of Data

In today’s fast-paced manufacturing environment, the ability to quickly adapt and optimize operations is crucial.

With Freedom IOT, we provide a comprehensive platform designed to streamline your processes, maximize efficiency, and create real business value. Revolutionize your operations with our powerful Analytics Intelligence platform, universal equipment connectivity, and seamless integration capabilities.

Universal Connectivity Across Your Equipment

The Freedom IOT platform connects effortlessly with virtually any type of manufacturing equipment—from the latest smart machines to legacy systems.

You don’t need to overhaul your infrastructure to achieve Industry 4.0 performance. Our technology ensures quick and flexible deployment so you can unlock hidden value across your entire operation.

Real-Time Insights That Drive Real-World Results

At the core of the FREEDOM®AI platform are robust analytics that compile data from multiple sources and offer actionable insights.

Our platform connects, collects, and combines enterprise data, feeding sophisticated AI models that improve decision-making and operational efficiency. From asset optimization to predictive maintenance, Freedom IOT gives you the information you need, when you need it.

Smart Manufacturing Starts with a Smart Platform

Understand more about your manufacturing operation including downtime tracking, part production, and Overall Equipment Effectiveness (OEE).

eLog Module

Visibility

Monitor downtime, track real-time production, analyze tool usage, and visualize OEE performance across your plant with one powerful module.

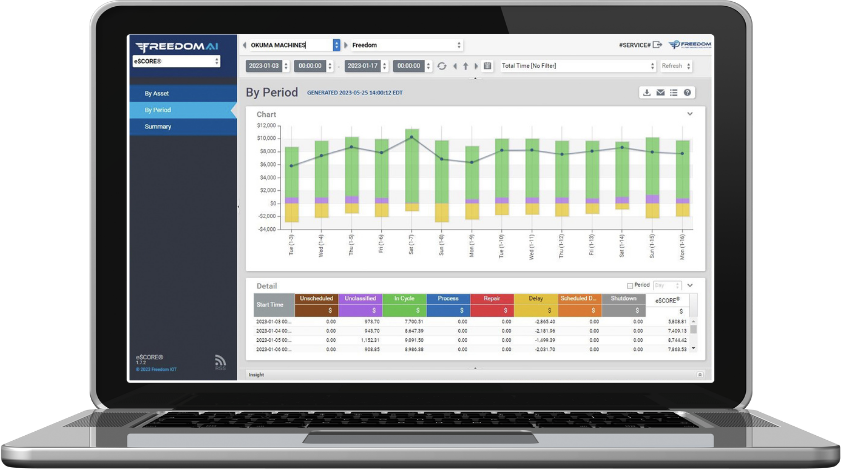

eScore

Profitability

Instantly see which machines, departments, or value streams make or lose you money with real-time profitability insights.

Shift Reports

Insight

Compare shift performance across machines to uncover capacity, staffing, and process improvement opportunities.

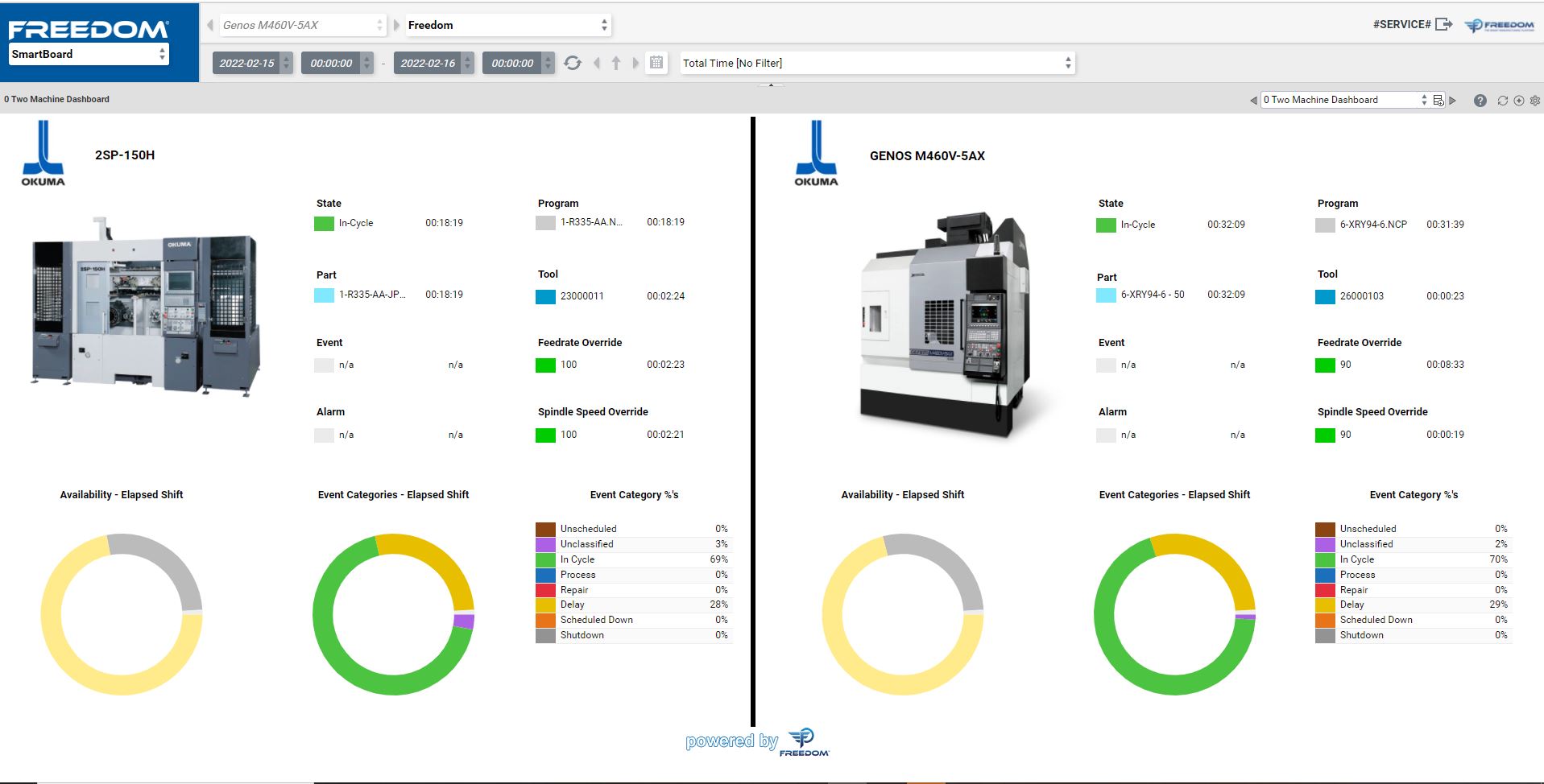

Machine Interfaces

Automation

Automatically track part numbers and quantities as they’re produced with seamless machine-to-platform communication.

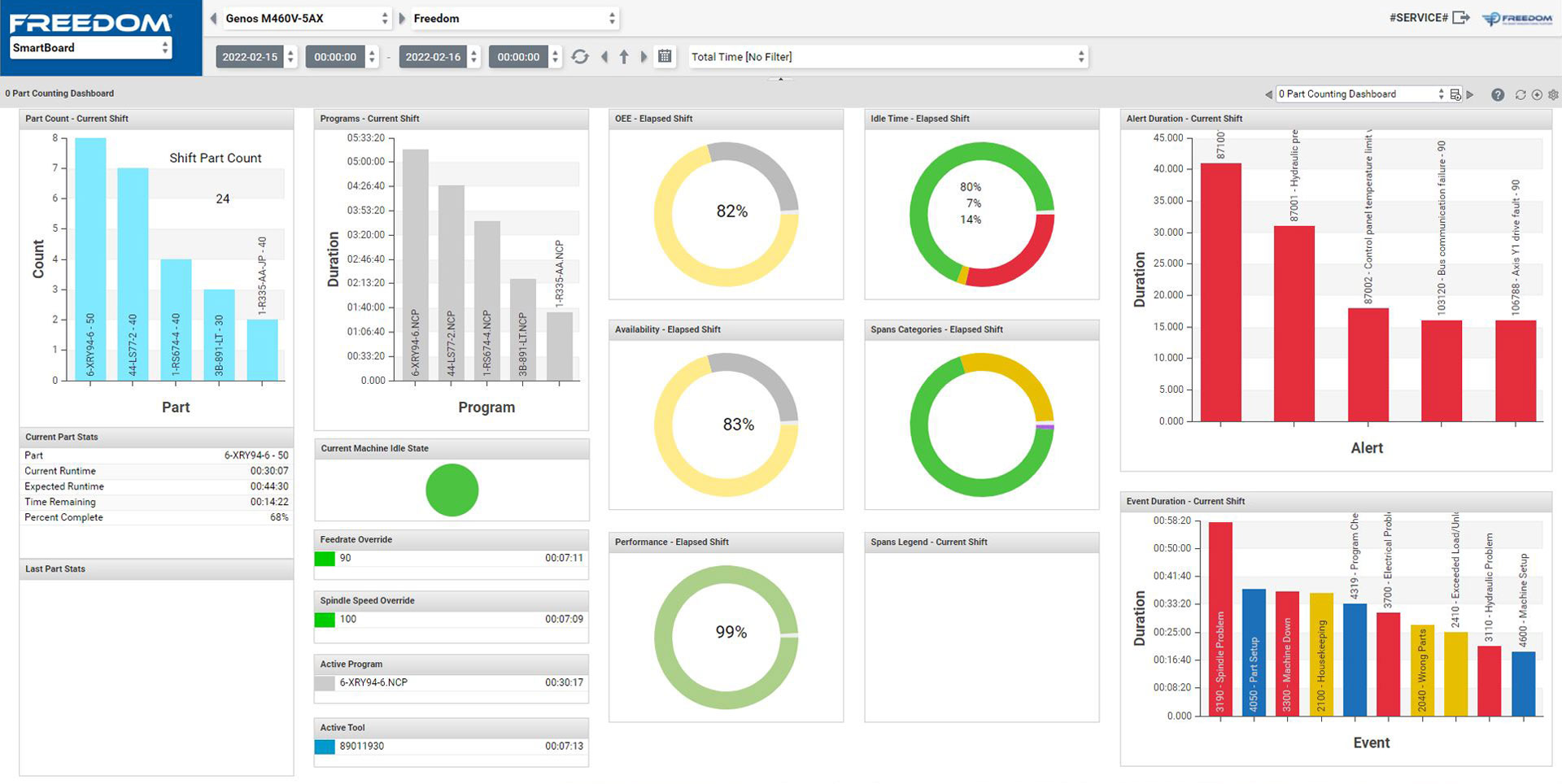

Take a Closer Look

Smarter Manufacturing Data

Events – Freedom lets users assign, manage, and analyze machine downtime events by category with detailed reports like pareto charts and searchable event lists.

Parts – Track and analyze production by part number and operation in real-time using automated part counting and cycle time reports.

Programs/Tools – View detailed reports on program and tool usage that are linked to each part number for better process insight.

OEE – Monitor plant-wide or machine-specific OEE and drill down to pinpoint performance, availability, and quality losses.

Real-Time ROI Tracking

- Real-Time Tracking – Instantly understand which machines or areas are generating profit—and which are draining resources—based on live performance data.

- Granular Insights – Break down profitability by machine, department, shift, or value stream to identify hidden inefficiencies or untapped potential

- Identify Inefficiencies Fast – Catch and correct performance issues before they turn into costly losses with alerts tied to profitability thresholds.

Shift Smarter

- Compare Shift Performance – Instantly evaluate how different shifts stack up in terms of machine utilization, part output, and downtime

- Optimize Capacity & Throughput – Uncover hidden capacity by identifying underperforming shifts or inconsistent output across the day.

- Actionable, Visual Reports – Shift-based KPIs presented in clear, filterable dashboards make it easy to share insights and drive improvements

Data Without Delay

- Seamless Machine Integration – Automatically collect real-time data from machines without manual input or disruption to production.

- Eliminate Manual Errors – Reduce the risk of human error with automated data capture directly from machines.

- Plug Into Any Environment – Designed to interface with a wide range of legacy and modern manufacturing equipment.

See the Full List of Features

Freedom eLog

- Metrics Report - OEE Metrics - Downtime Event Analytics - Flexible Shift Scheduling - Part Production Reports

e$CORE

- Factory Income Statement - Parts Profit/Loss Reports

Machine Interfaces

- Standard Data Items - Auto Part Counting

Notification Module

- Email Reports - Text Message Alerts - Condition-based Triggers

Shift Reports Module

- Shift Comparison Reports

Real-Time Dashboard

- User-Defined Dashboards

Slideshow Module

- Dashboard Visualization

Operator App

- Application for Operators Use on the Shop Floor

Seamless Integration Across Your Business Systems

Protocols

Freedom IOT’s platform supports integration with several key industrial communication protocols and controllers, including:

CNC Controllers

Including but not limited to Fanuc, Siemens, Heidenhain, Bosch, Mazak, and Okuma.

PLCs

Such as Allen-Bradley (A-B), Siemens, and Modicon

Robots

Including Fanuc, KUKA, and ABB.

Legacy Machines

Freedom IOT can integrate with older equipment lacking modern communication interfaces by using sensor adapters and hosting appliances.

Deploy Freedom AI However You Like

With two installation options to choose from and web browser access, we can adapt to fit your needs:

On-Premise

Customers can choose to deploy the Freedom AI platform on a virtualized server within their own infrastructure. Once the virtual server is created, the Freedom team installs and configures the software; often times remotely.

Industrial Cloud

Our Freedom AI Industrial Cloud option is a scalable multi-tenant solution that is hosted externally on a third-party hosting service.

Web Browser Access

No special software to install on user devices, all you need is a web browser.

What Our Customers are Saying

Optimize Production.

Boost Revenues.

- Listen to Your Machines

- Analyze Health & Production

- Optimize & Maximize Workflow