FREEDOM eLOG®

eLOG is a cloud-based software suite that seamlessly “Connects and Collects™” production asset data to dramatically improve efficiency by providing our customers full transparency of manufacturing information, with reports and analytics for optimization of machine health, process health, and OEE from the shop floor to the top floor. eLOG is the industry leading Smart Manufacturing Platform.

Idle manufacturing assets means diminished productivity.

A basic function of managing any manufacturing operation is knowing what your assets are doing at any given time.

If they’re not being efficiently utilized, then why? – Freedom eLOG’s core metrics will show you planned versus actual run time – in real time – for any industrial asset, providing the insights you need to achieve smooth, uninterrupted, highly profitable production.

The Freedom® AI platform can liberate the data that’s been trapped in your machines, and enhance it with the knowledge of your plant floor teams to help you discover opportunities for improvement related to unplanned downtime.

These areas can include:

- Maintenance

- Component Failures and Repair

- Tool Changeover and Tool Management

- Part Setup

- Gauging & Inspection

Get real-time answers.

Understanding the Overall Equipment Effectiveness (OEE) in the blink-of-an-eye can be pivotal in ensuring the ongoing seamlessness of your production scheduling. Time IS money.

OEE

The Overall Equipment Effectiveness (OEE) Core aggregates data from the Availability, Performance, and Quality Cores, allowing your team to quickly understand whether production is headed in the right direction.

World-class operations run at 85% OEE or better. The FREEDOM AI platform informs your team just how close you are to that target and which aspects of your operations are holding you back from exceeding it. You’ll be able to drill down into the OEE reports to see if it’s the availability, performance, or quality metrics influencing your OEE score, and respond accordingly.

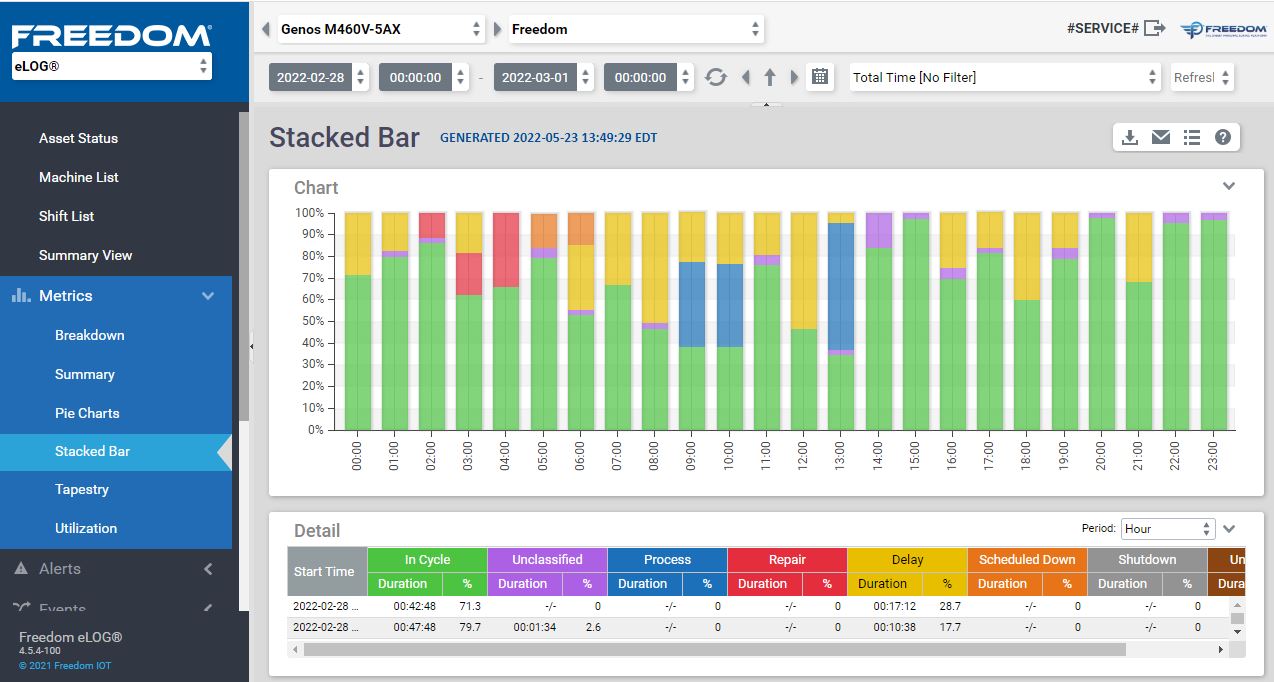

Availability, Automatically

The FREEDOM AI platform automatically collects and displays in-cycle, alarm and alert conditions, and generates idle time events allowing users to better understand when, why, and how a machine has stopped, as well as how long it has been in that state.

The notification feature will email or text relevant personnel based on user configured triggers from alarms, alerts, or other downtime events.

Get up to Speed

Freedom eLOG’s core Performance metrics informs users if a particular machine is producing at the expected output. In other words, it answers the question: is this machine performing at rate? As with all of the Freedom platform’s core modules, Performance leverages data from plant floor assets in addition to user-defined information – such as your manufacturing standards – to get the answers you need, specific to your operations.

For example, is your asset making 10 parts per hour as expected? If not, Performance enables teams to drill down into the data to determine why. This all happens in real-time, so you can take corrective action when it really matters.

Productivity is in the Details

The Freedom platform’s Quality Core provides an intuitive and streamlined process for recording Good Parts and Bad Parts. Based on the standards set for each machine and cycle, a graphical representation is generated to show the ratio of good parts to the total parts produced.

Alerts can be triggered based on defined parameters, allowing each user to investigate potential Yield issues.

Digital Details

While a machine operator can sometimes assess whether a part was good or bad, it can be difficult to ascertain the true nature of a part until it’s fully inspected.

Once inspection data is available, the Freedom platform’s Quality metrics allow you to edit good parts / bad parts information for your quality reports.

FREEDOM® eLOG's unique ability.

The Top 25 Reports automatically organize and prioritize Alarms/Alerts or Downtime Events according to the impact they’re having on your operations.

The Freedom platform’s unique ability to view the data in multiple perspectives provides users with a choice of creating the reports based on Frequency or Duration.

Case in-point – Availability in Action: