What is Waste in Manufacturing?

Lean manufacturing is a method for improving manufacturing efficiency and reducing waste in the manufacturing process. In lean manufacturing, waste is defined as any activity or process that does not add value to the product or service.

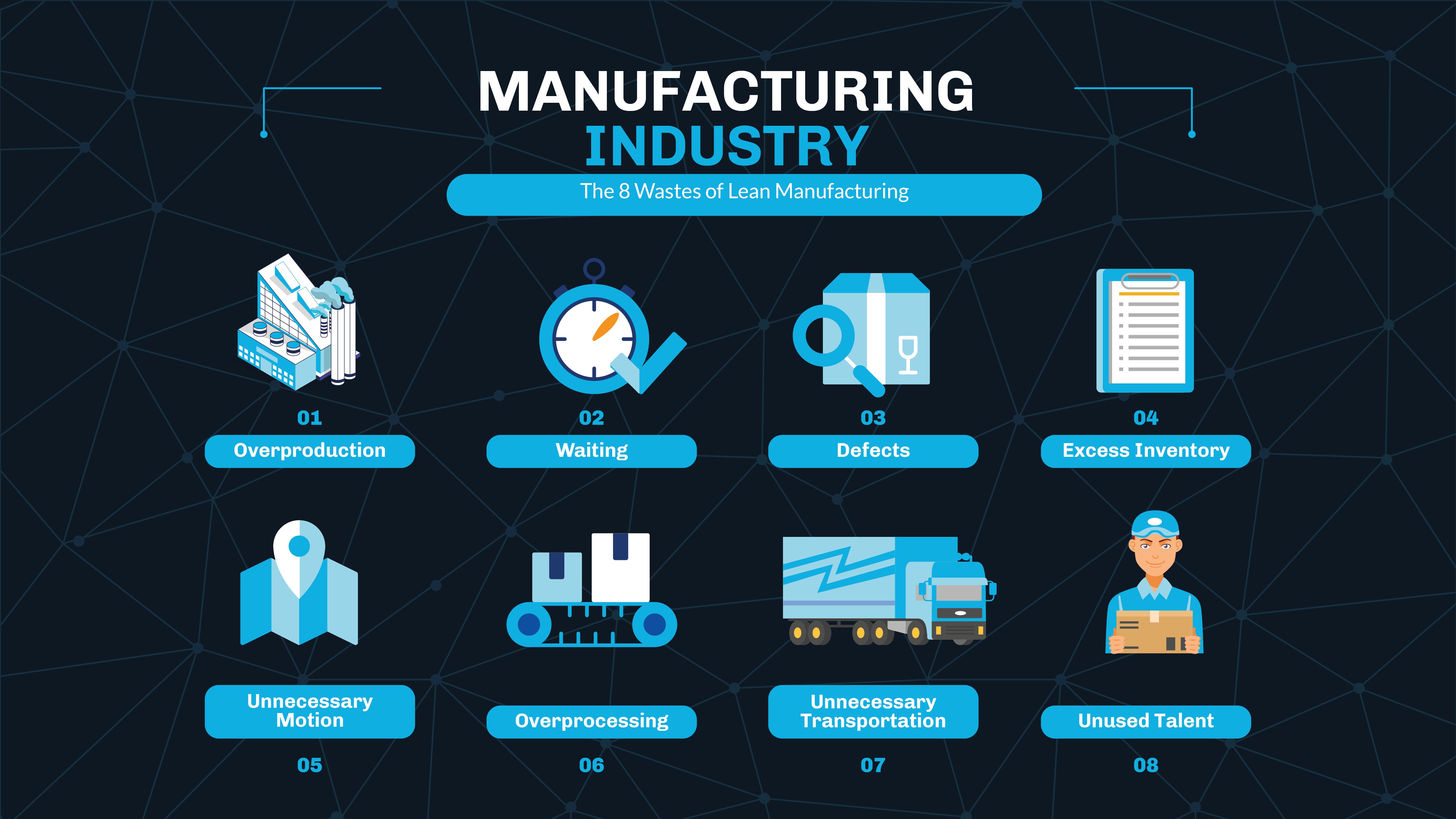

One of the key components of lean manufacturing is identifying and eliminating the 8 wastes, also known as “muda.” These wastes can be found in every manufacturing process and eliminating them leads to significant improvements in productivity, Overall Equipment Effectiveness (OEE), and profitability.

1. Overproduction

This waste occurs when more products are made than are required. Overproduction can happen when manufacturers produce items ahead of schedule in order to meet future demand, or when they produce more than what the customer has ordered. Overproduction can be a significant waste in the manufacturing process because it ties up resources, such as raw materials and equipment, that could be used more efficiently elsewhere. Additionally, it can lead to excess inventory and higher storage costs.

How to reduce overproduction

To reduce overproduction, manufacturers should focus on producing only what is needed, when it is needed. This can be accomplished through careful planning and scheduling, as well as implementing pull systems, such as kanban, that allow for just-in-time production.

2. Waiting

Waiting occurs when products or materials are not moving through the production process as quickly as they should. Waiting can happen when there are delays in the delivery of raw materials, or when there are bottlenecks in the production process that cause delays. Waiting can be a significant waste in the manufacturing process because it reduces the overall efficiency of the production line and can cause delays in the delivery of goods or services to the customer.

How to reduce waiting

To reduce waiting, manufacturers should focus on streamlining their processes, eliminating bottlenecks, and balancing capacity. This can be accomplished through process mapping, which allows manufacturers to identify the areas where delays are occurring, and then implementing solutions to address those issues.

3. Defects

Defects are common waste in manufacturing and can occur at any point in the production process. Defects can happen when there are errors in the production process, or when there is a lack of proper quality control. Defects can be a significant waste in the manufacturing process because it leads to rework, scrap, and customer dissatisfaction. It also consumes resources and time that could be used more efficiently.

How to reduce defects

To reduce defects, manufacturers should focus on improving quality control and implementing statistical process control (SPC) methods to monitor and improve the production process.

4. Excess Inventory

Excess inventory is a waste that occurs when manufacturers have more materials or products on hand than they need. Excess Inventory can happen when manufacturers produce more than what the customer has ordered, or when they hold on to materials for longer than necessary. Excess inventory can be a significant waste in the manufacturing process because it ties up resources, such as money and space, that could be used more efficiently elsewhere. Additionally, it can lead to higher storage costs, and it can also result in the obsolescence of the materials.

How to reduce excess inventory

To reduce excess inventory, manufacturers should focus on implementing pull systems such as kanban, which allow for just-in-time production and help to keep inventory levels under control.

5. Unnecessary Motion

Unnecessary motion is a waste that occurs when employees or automation are performing tasks that are not needed or are inefficient. Unnecessary Motion can happen when employees are required to move around the factory or office to perform their duties, or when equipment is not properly positioned to minimize the distance that materials need to be moved. Unnecessary motion can be a significant waste in the manufacturing process because it consumes time and energy, and it can also lead to an increased risk of injuries.

How to reduce unnecessary motion

To reduce unnecessary motion, manufacturers should focus on ergonomics and process improvement, as well as implementing work cells and other work simplification methods.

6. Overprocessing

Overprocessing is a waste that occurs when manufacturers are using more resources such as time, tools, or unnecessary processes than are needed to produce a product. Overprocessing can happen when manufacturers use unnecessarily complex equipment or processes, or when they add additional steps to the production process that do not add value to the final product or service. Overprocessing can be a significant waste in the manufacturing process because it consumes resources such as time, money, and materials and it can also lead to increased defects and lower quality of the final product or service.

How to reduce overprocessing

To reduce overprocessing, manufacturers should focus on simplifying their processes and eliminating unnecessary time or steps.

7. Unnecessary Transportation

Unnecessary transportation is waste that occurs when products or materials are transported more than necessary. Unnecessary Transportation can happen when materials are moved around the factory or office without a clear purpose, or when products are shipped unnecessarily. Unnecessary transportation can be a significant waste in the manufacturing process because it consumes resources such as time, money and energy and it can also lead to an increased risk of defects and damage to the final product.

How to reduce unnecessary transportation

To reduce unnecessary transportation, manufacturers should focus on implementing effective layouts, such as those based on flow principles, and using conveyors and other material handling equipment to streamline the transportation of products and materials.

8. Unused Talent

Unused talent is a waste that is not related to manufacturing process issues, but rather company management not leveraging all the employee talent in their operations. Unused talent can happen when employees are not given the opportunity to use their skills and knowledge, or when they are not provided with the appropriate training to perform their jobs effectively. Unused talent is considered a waste in lean manufacturing because it represents a missed opportunity to improve efficiency and increase productivity.

How to reduce unused talent

Eliminating this waste requires managers to thoroughly examine the skills and knowledge their employees possess and put them to use to improve manufacturing operations.

How Freedom AI Helps Improves Waste

Freedom AI’s Intelligent Automation Software helps by identifying, classifying, and visualizing these wastes in real-time and greatly improving manufacturing efficiency. As a leader in machine monitoring software, we focus on providing valuable insights that enable real-time, data-driven decisions. By providing real-time notification of manufacturing events and alerts delivered by SMS, email, or RSS feeds, Freedom AI ensures that information is shared across functional departments and up the chain of command.

Conclusion

In conclusion, the eight wastes in manufacturing are commonly found in every manufacturing process, by identifying and eliminating these wastes, manufacturers can greatly improve their efficiency and profitability. Implementing lean manufacturing practices such as process mapping, just-in-time production, and statistical process control can help manufacturers to identify and address these wastes, and ultimately improve their bottom line. The use of machine monitoring software and analytics intelligence platform such as Freedom AI greatly assists in identifying and eliminating these wastes.