Say Goodbye to Clutter: How to Make Your Shop Floor Go Paperless

Discover how to streamline your production operations by going paperless. Learn practical tips and tools to digitize your processes, reduce paper waste, and increase productivity. Read now to start your journey toward a more sustainable and efficient workplace.

How to Reduce the 8 Wastes in Manufacturing

Read Freedom AI’s article on what is waste in manufacturing, the 8 different types of waste in manufacturing, how to reduce waste, and how Freedom AI can help make it happen.

How to Improve Your CNC Monitoring

Gearing up to understand CNC monitoring? You’ve come to the right place. We’re here to explore what it is, what data you can monitor, as well as how to take your overall monitoring game to the next level with the help of Freedom AI.

Let’s start by delving into what CNC monitor is all about! CNC monitoring is the process of extracting information from CNC machines to examine the machining activity happening in your factory. This technique allows you keep track of key performance indicators in real-time and to safeguard against unanticipated issues or disruptions.

The 5 Most Important Lean Manufacturing Metrics To Achieve Operational Success

Lean manufacturing strives to boost customer value by improving efficiencies and reducing waste across operations. Moving toward lean manufacturing requires more effective management of materials, human resources, and energy. Compiling and analyzing the right data is crucial to the success of lean manufacturing.

What Is Machine Monitoring?

Machine monitoring harnesses the power of the industrial internet of things (IIOT) to ensure manufacturing processes run smoothly. If you are new to the concept and want to find out how it can boost manufacturing productivity, we’ve put together a helpful guide below.

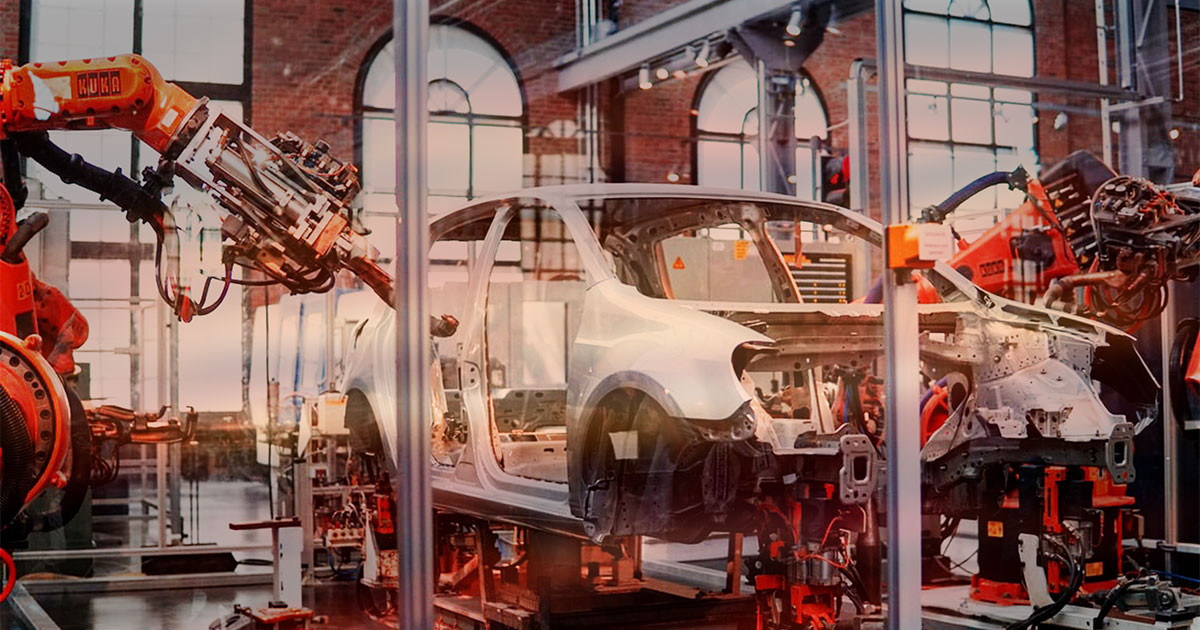

Complete Guide to Smart Manufacturing

Smart manufacturing is a technology-driven approach that utilizes Internet-connected machinery to monitor the production process. The goal of smart manufacturing is to identify opportunities for automating operations and use data analytics to improve manufacturing performance.

Five Fundamental Keys to Manufacturing Efficiency

Functional excellence is not enough to stay competitive in today’s manufacturing landscape. Maintaining a profitable, competitive and sustainable business today requires that organizations achieve efficiencies across each stage of the value stream.

How to Measure Manufacturing Efficiency

If you own a manufacturing business, one of the key rules to achieving sustained growth is ensuring your operations are efficient. Regardless of the items you are producing, you must track the entire production process to assure your workforce is diligent, your machinery works well, and your maintenance costs remain as low as possible.

The Modern Manufacturer and the Smart Factory

As technology has changed at a rapid pace, so has manufacturing. Only twenty years ago, practically nothing had internet access. Now, it is hard to find something without internet access. A common way to explain how the manufacturing sector has changed is by referencing the steps of technological advancement that the manufacturing industry has taken.

IoT Challenges Debunked

Some of the most commonly discussed IoT challenges that prevent implementation are the financial investment risk and legacy infrastructure. From a financial standpoint, the investment may vary drastically depending on the number of IoT devices connected and platform used.