CNC Machine Monitoring Software

Freedom IOT is transforming IoT machine monitoring software by offering a custom solution for shop floors – fully automated CNC machine monitoring systems that provides users with real-time production data visualization, immediate alerts, and comprehensive historical analytics.

Our CNC machine monitoring software empowers factory workers, supervisors, and management alike to make quick, informed, and confident decisions grounded in the latest data insights.

Trusted by leading manufacturers:

Freedom IOT's Machine Monitoring Software

Welcome to the future of machine monitoring

In an era where data-driven insights pave the way for optimized operations, Freedom IOT stands at the forefront of innovation. We offer a next-generation solution that empowers manufacturers with a comprehensive view of their production processes.

Whether you’re a small enterprise or a global corporation, our state-of-the-art platform seamlessly connects and collects data from your shop floor, translating it into actionable insights. From real-time machine monitoring to deep historical analytics, our software heralds a revolution in manufacturing efficiency, transparency, and predictability.

Experience the power of artificial intelligence blended with IoT as we redefine sustainable and efficient manufacturing with Freedom IOT.

Key Benefits of Machine Monitoring Software

Freedom's all-in-one machine monitoring

Powered by FREEDOM®AI, our platform revolutionizes the way you manage your industrial operations by bringing valuable insights right to your fingertips.

With FREEDOM®AI, you gain the power to optimize assets, streamline inventory, finesse production schedules, increase output, and predict maintenance needs. FREEDOM®AI connects, collects and combines enterprise data from multiple sources, feeding AI models and serving real-time insights to help you make the most informed decisions for your business.

Key benefits of production monitoring software include:

Improved Manufacturing Efficiency

Predictive Maintenance

Enhanced Productivity

Automated Data Collection

Increase in OEE

Reduced Operating Costs

Improved Machine Utilization

Real-time alerts & notifications

Improved Quality Assurance

Customized Reporting

How Machine Monitoring System Works

CNC Machine Monitoring

1: Collect

Initiate the machine monitoring process by gathering data from every machine control and operator on the production floor. Through various sensors and devices installed on the machinery, a vast amount of operational data including performance metrics, operational efficiency, and anomalies is gathered in real-time.

2. Secure

Once data is collected, it's crucial to secure it to maintain integrity and confidentiality. The data is encrypted and securely transferred to a centralized system or cloud storage, ensuring that it remains protected against unauthorized access or cyber threats.

3. Access

With the data securely stored, authorized users can then access this information. Depending on their role within the organization and required privileges, users may access different levels of data to perform their job responsibilities effectively.

4. Visualize

The collected data is then processed and visualized through intuitive dashboards. These visual representations make it easier to comprehend complex datasets, allowing users to see patterns, trends, and anomalies at a glance.

5. Monitor

Continuous monitoring is vital. The system provides real-time updates on machine performance and health, enabling immediate detection of any operational issues. This step ensures that any anomalies are caught as they happen.

6. Analyze

The next phase is to analyze the data. By applying advanced analytics and AI models, the system can identify underlying trends, predict potential failures, and provide actionable insights that might not be immediately obvious through manual analysis.

7. Improve

Based on the insights gained from the analysis, strategies can be formulated to improve efficiency, reduce waste, and enhance production capacity. This stage is about translating data into actionable changes within operations.

8. Empower

Finally, the entire process empowers organizations and their employees by providing them with the tools and insights they need to make informed decisions. It fosters a data-driven culture where every action and strategy is backed by reliable, real-time data leading to improved business outcomes and operational excellence.

Machine Monitoring Software Features

what you get From Freedom

Integrations or manual data entry? The choice is easy. Freedom AI can pull data from a variety of business systems, reducing manual effort and minimizing errors. Whether it’s populating maintenance tickets, estimating cycle times, or tracking performance metrics, Freedom AI’s seamless integration gets the job done.

In the demanding and dynamic environment of manufacturing and industrial sectors, operational excellence is not just an objective; it is a fundamental necessity. FREEDOM®AI’s pioneering machine monitoring software is engineered to empower your operations with unparalleled efficiency and insight. Here’s how:

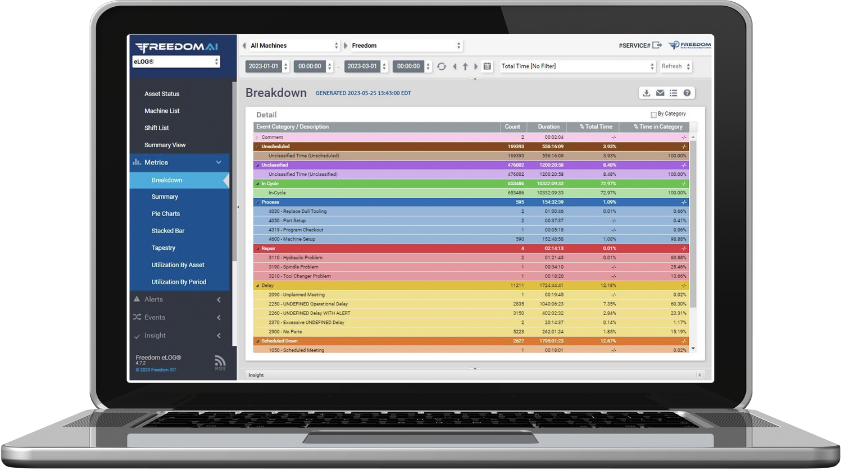

Machine Downtime Tracking

Downtime is the adversary of productivity. FREEDOM®AI offers sophisticated downtime tracking capabilities, pinpointing the root causes of machine idleness. By identifying and categorizing downtime events, our software enables targeted interventions, reducing idle time and boosting overall equipment effectiveness (OEE).

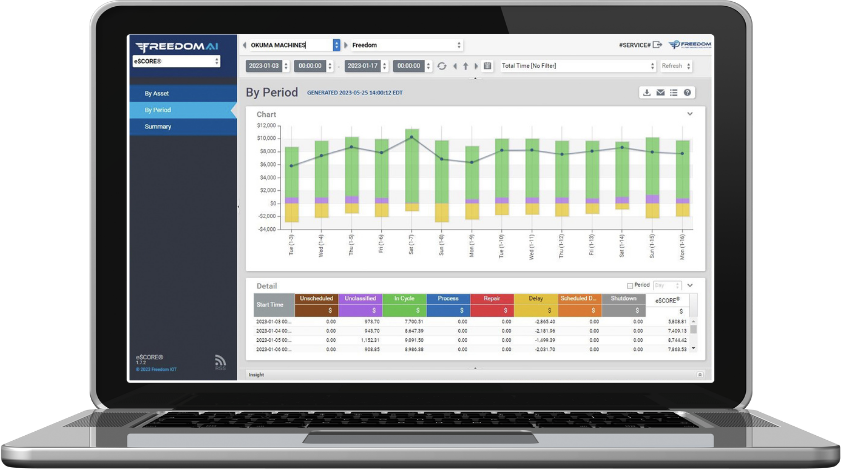

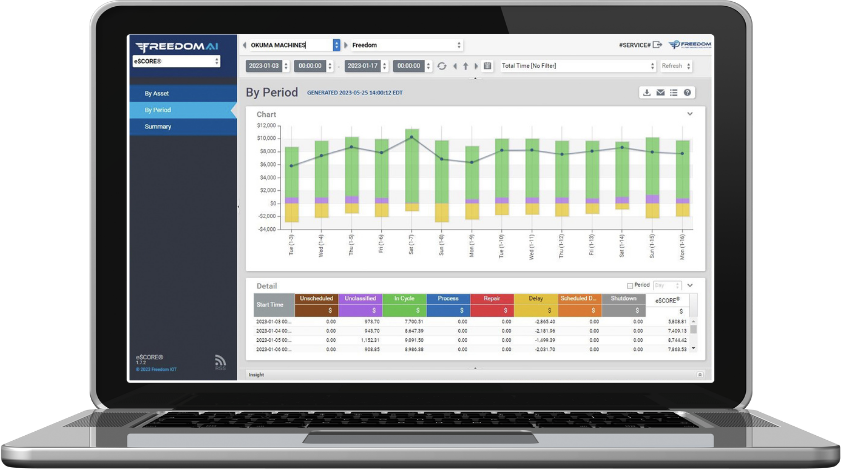

Real-Time Alerts and Dashboards

Stay ahead of potential issues with FREEDOM®AI’s real-time alerts and customizable dashboards. These features ensure immediate notification of critical events, allowing for swift action to mitigate disruptions. Our intuitive dashboards provide at-a-glance insights into operational status, making data-driven decisions not just possible but straightforward.

Alerts and Notifications

Precision-targeted alerts and notifications are central to FREEDOM®AI’s proactive management ethos. These tools keep you informed of performance thresholds and operational anomalies, ensuring that your team can respond with accuracy and agility to any scenario.

OEE Performance Reporting

Optimizing for OEE is optimizing for profitability. FREEDOM®AI provides detailed OEE performance reporting, delivering insights into the three critical components of availability, performance, and quality. Leverage our analytics to drive continuous improvement and maximize the return on your machinery investments.

Quality Tracking and Reporting

Quality is non-negotiable. With FREEDOM®AI, track and report on the quality aspects of your operations with unprecedented precision. Our software helps you uphold the highest standards, ensuring that quality metrics are not only met but exceeded.

Machine Utilization Reporting

Maximize asset performance with FREEDOM®AI’s machine utilization reporting. Understand how each machine contributes to your operations, identify underutilized assets, and recalibrate for optimal use. Our utilization insights support strategic decision-making, enhancing both productivity and profitability.

How Machine Monitoring Helps ROI

Freedom's CNC Machine Monitoring Software

Harnessing the transformative power of FREEDOM®AI’s machine monitoring software, manufacturers can illuminate the path to a improved ROI.

Operational Efficiency and Optimization

By providing valuable insights into machine health and process health, Freedom's platform enables predictive maintenance, preventing unforeseen machine downtime and ensuring efficient use of assets. Moreover, it uncovers areas of improvement within production schedules and inventory management, accelerating output and minimizing wastage, leading to cost savings.

Reducing Manual Effort and Minimizing Errors

Freedom's platform automatically gathers and analyzes data from multiple business systems. This automation diminishes manual data-entry labor, drastically reducing the margin for error and time-consuming effort of consolidating data for decision making. The reduced operating costs improve the ROI.

Process Insight and Enhanced Decision-making

By offering real-time manufacturing production data and historical analytics, the platform facilitates informed decision making. Whether it's tracking good versus bad parts produced or comparing estimated cycle times to actuals, these insights lead to strategic decisions that increase production efficiency, quality, and, consequently, profitability. This intelligence consequently enhances the ROI.

Get Real-time Precision Data

Click the button below to start your 90-day free trial of Freedom IOT software and revolutionize your machine workflow.

Client Testimonials

What our CUSTOMERS are saying, and case studies prove.

Get Started with Freedom

Take the first step in optimizing your machine shop with Freedom IOT today.