Menu

- 60-DAY FREE TRIAL

Put your process to the test with a 60-Day Free Trial of FREEDOM®AI and see what it can do for you.

Put your process to the test with a 60-Day Free Trial of FREEDOM®AI and see what it can do for you.

Discover the pinnacle of smart manufacturing with Freedom IOT, a cutting-edge solution designed to transform your operations through advanced analytics and seamless system integrations. Elevate efficiency and innovation in your manufacturing processes with our customizable and user-friendly platform, tailor-made for the modern digital factory.

Trust in Freedom IOT to lead your journey towards optimal performance and industry-leading smart manufacturing practices.

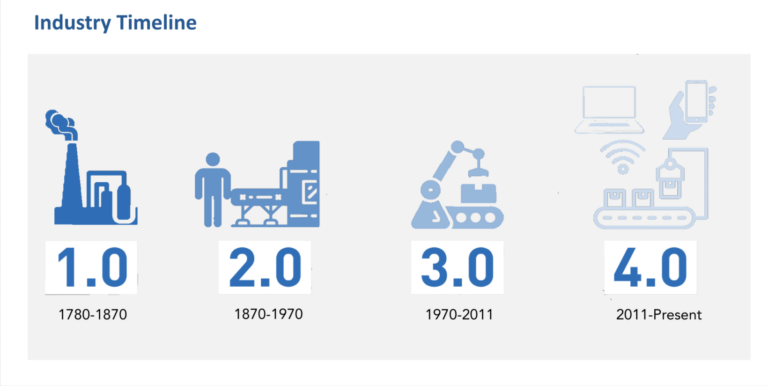

Smart Manufacturing is the gateway to a revolutionized industrial landscape, embracing the digital transformation of factories into environments where intelligence drives production. It represents an integration of data from all corners of the manufacturing process, enabling automated systems to make informed decisions, streamline operations, and enhance productivity.

At the core of Industry 4.0, smart factories leverage the power of advanced technologies to create a highly adaptable and efficient manufacturing ecosystem. These futuristic facilities are characterized by their ability to self-optimize performance across a broad network of machines, sensors, and production units, rooting for an era of unlimited potential in manufacturing possibilities.

Technologies for smart manufacturing are evolving to dramatically enhance production capabilities. Additive Manufacturing (3D Printing) has matured as a technology, anticipating robust growth and extending its applications in producing highly customized products with various materials like metals and ceramics. The technology accelerates rapid prototyping, increases design efficiency, and supports material efficiency with complex geometries.

Nanotechnology focuses on manipulating matter at the nanoscale, facilitating advancements from lighter vehicles and improved electronic devices to efficient solar panels and enhanced cancer treatments. Over $25 billion has been invested in this field by federal agencies since 2001, highlighting its significance.

Cloud Computing has redefined data handling by offering services like IaaS, PaaS, and SaaS through public, private, and hybrid clouds. Significant developments marked by the launch of platforms like Amazon EC2 and Salesforce have underscored its benefits such as cost efficiency, scalability, increased productivity, and reliability.

Lastly, the Industrial Internet of Things (IIoT) integrates operational technology with informational technology, enabling real-time analytics, predictive maintenance, and improved decision-making processes through enhanced transparency in machine and process health monitoring.

These technologies collectively push the boundaries of what is possible in smart manufacturing, ensuring efficiency, innovation, and superior performance in industrial operations.

Embracing smart manufacturing with Freedom IOT unlocks numerous benefits: significant efficiency improvements, reduced operational costs, enhanced product quality, and superior flexibility in production processes.

It enables predictive maintenance, minimizes downtime, and ensures a seamless digital transformation journey towards optimized assets and production schedules.

Achieve significant gains in operational efficiency through intelligent automation and data-driven decision-making.

Minimize downtime and extend equipment life by anticipating maintenance needs before failures occur.

Adapt swiftly to market changes and custom orders with agile manufacturing processes.

Lower expenses related to production, maintenance, and energy consumption by optimizing processes.

Leverage real-time analytics to improve precision, reduce defects, and ensure consistently high-quality outputs.

Navigate the complexity of digitizing manufacturing operations with a comprehensive, easy-to-integrate solution.

Leverage the power of advanced AI to connect, collect, and combine data from multiple sources into actionable insights, driving operational optimization.

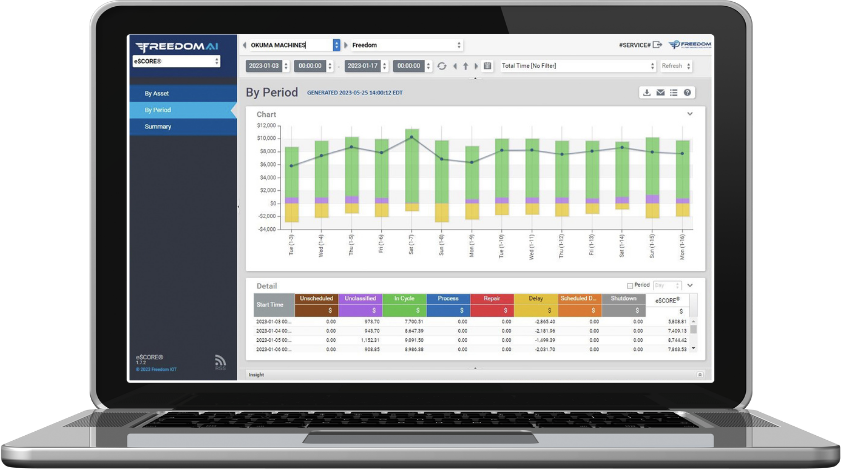

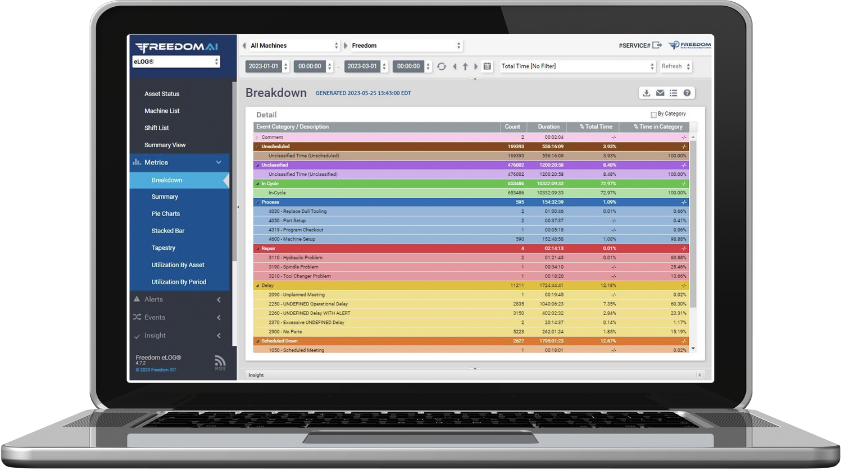

Provide interactive, tailored views of real-time data and analytics, facilitating quick, informed decision-making in smart manufacturing.

Freedom’s eLog offers unparalleled flexibility, allowing you to choose between cloud-based or on-premise data hosting, unlike competitors who mandate cloud storage.

Effortlessly pull data from MES, CMMS, QMS, and ERP systems to reduce manual efforts and minimize errors.

Populate maintenance tickets, compare estimated versus actual cycle times, and track production quality with ease.

Navigate through comprehensive standard reports and utilize point-and-click interfaces without the need for special configurations or developments.

Watch our in-depth webinar from our CEO Jeff Price about the basics of modern manufacturing, to the intricacies of the Smart Factory and how your operations can be improved using newly founded technology.

Take the first step in optimizing your machine shop with Freedom IOT today.