What is OEE?

Overall Equipment Effectiveness (OEE) is widely considered the best manufacturing KPI (Key Performance Indicator) for measuring the efficiency of production processes. In other words, it offers manufacturing leaders actionable data regarding the performance of machinery, plants, lines, and cells. Let’s take a deeper dive into defining and understanding what is OEE.

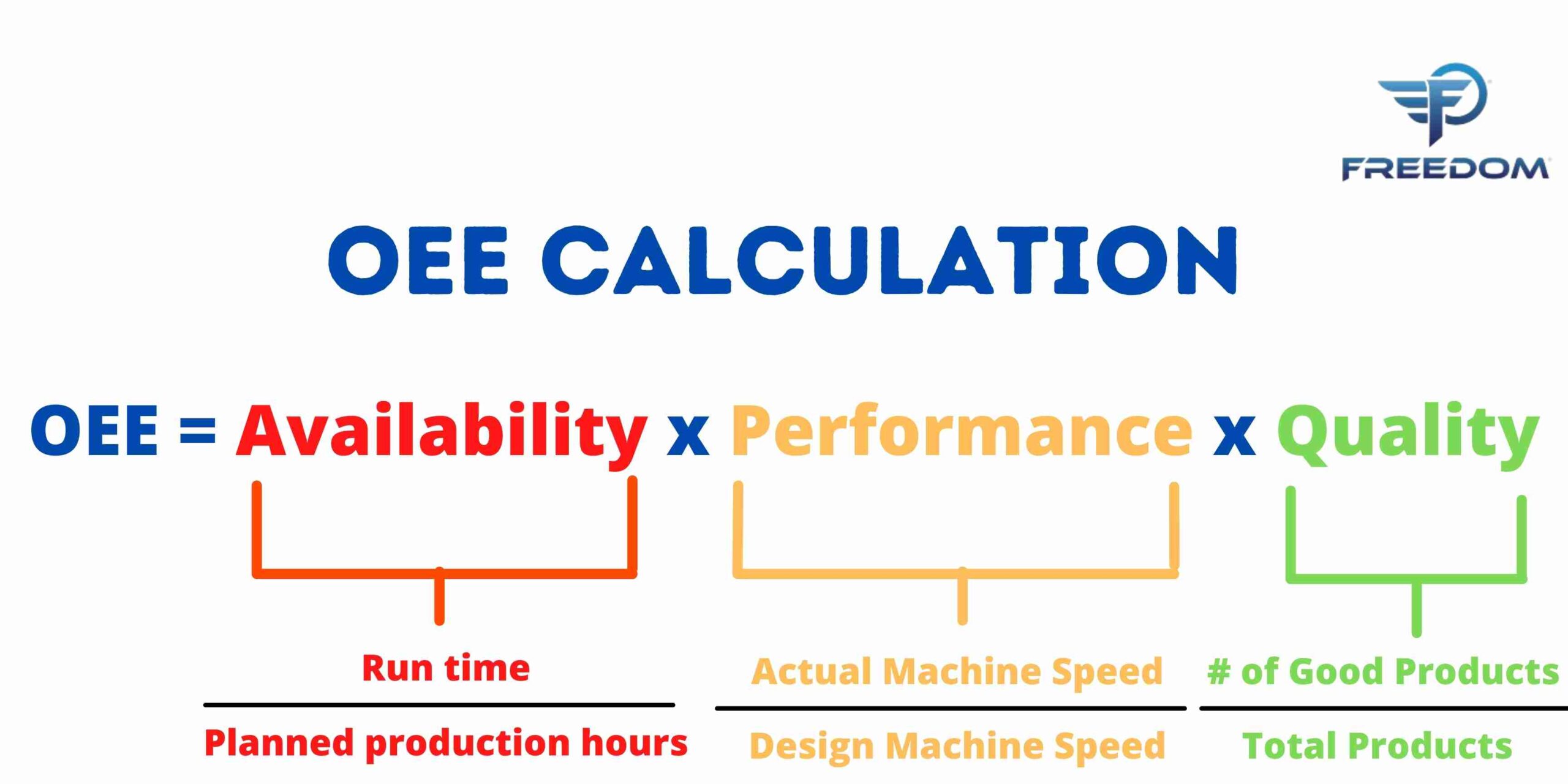

The logic behind OEE is simple: it accounts for productivity losses incurred during a defined period and divides them into three categories, including:

- Availability

- Performance

- Quality

The availability metric measures production losses associated with downtime, while the performance and quality metrics refer to losses related to reduced speed and discarded units, respectively.

These metrics are represented as percentages and multiplied together to come up with a final OEE measurement. The higher the final percentage, the more efficient the production processes of the manufacturer in question.

Working out your company’s OEE could help to pinpoint areas for operational improvement and, therefore, boost your output and profits. So, how can you calculate your OEE?

How to Calculate OEE

To start your OEE calculation, you need to determine how much time is available for production at your plant. From this, you should subtract any time for planned production pauses such as lunch breaks and planned maintenance sessions. The number you end up with is known as planned production time. OEE analysis subtracts efficiency losses from this planned production time.

Measuring losses

As already mentioned, losses fit into three KPI categories. Here is how to measure them:

- Availability: This metric deals with losses related to downtime caused by malfunctioning equipment, shortages of materials, employees changing shifts, or any other disruptive events. To calculate an availability percentage, divide the amount of actual uptime by the planned production time during a given period.

- Performance: The performance metric measures losses related to the speed of the production line. It may vary widely over time depending on the types of products you produce. Generally speaking, however, poor performance outcomes are often related to operator inefficiencies, old or inadequate machines, and the use of low-quality raw materials. To calculate your performance percentage, divide your ideal cycle time by your real cycle time or your real manufacturing speed by your ideal manufacturing speed.

- Quality: Finally, quality deals with losses incurred due to goods not passing quality checks. This includes goods that are downgraded or reworked. A quality percentage can be determined by dividing the number of quality-approved units produced by the total number of units produced during a set period.

OEE Formula

You can calculate the final OEE by multiplying together the three above factors, expressed as decimals. In other words, if your availability, performance, and quality percentages are 88.4%, 92% and 95.8%, respectively, the calculation and resultant OEE percentage is as follows:

OEE Formula example:

0.884 x 0.920 x 0.958 = 0.779 (77.9%)

Although OEE is one of the best metrics for tracking plant progress, identifying machinery issues, and catching production losses before they cause serious problems, it is not the only metric you should be looking at. Remember to look at granular issues within the three separate categories that fall under OEE and think about how they may impact your efficiency.

If you would like to see where you stand in terms of OEE and where you can improve, use this ROI calculator, fill in the highlighted areas, and take the first step. If you need help, a Freedom AI manufacturing specialist will be glad to help walk you through it.

OEE Software

If you’re looking for the best OEE software on the market, Freedom AI’s platform covers everything you need.

Freedom® AI software benefits:

- Monitors machine availability utilizing the machine, user, and system-generated events. Our OEE Software tracks machine cycle times as well as an asset’s plant operating time and delay times.

- Calculates an asset’s Performance by comparing the automatically collected machine data and data input by the operator with the standard (expected) process.

- Calculates an asset’s Quality by comparing the number of confirmed good parts recorded to the total number of parts produced.

- Reports OEE data related to when the machine is running and gives you a snapshot of how efficient your operation is performing.

For more information about the Freedom AI Smart Manufacturing Platform, contact Bill Horwarth at 513-719-1601 and info@freedomiot.com