OEE As A KPI

The manufacturing industry is more competitive now than ever before. Customers are limiting their spending, yet the costs of operating and materials remain high. This is pushing companies to re-evaluate how they work and improve their levels of efficiency.

A Guide to Factory Floor Monitoring

Data collection from the factory floor is a crucial part of improving manufacturing processes. The data can be used to determine how well machines are operating and what areas need improvement, which will lead companies down new paths for success.

Complete Guide to Smart Manufacturing

Smart manufacturing is a technology-driven approach that utilizes Internet-connected machinery to monitor the production process. The goal of smart manufacturing is to identify opportunities for automating operations and use data analytics to improve manufacturing performance.

Five Fundamental Keys to Manufacturing Efficiency

Functional excellence is not enough to stay competitive in today’s manufacturing landscape. Maintaining a profitable, competitive and sustainable business today requires that organizations achieve efficiencies across each stage of the value stream.

How to Measure Manufacturing Efficiency

If you own a manufacturing business, one of the key rules to achieving sustained growth is ensuring your operations are efficient. Regardless of the items you are producing, you must track the entire production process to assure your workforce is diligent, your machinery works well, and your maintenance costs remain as low as possible.

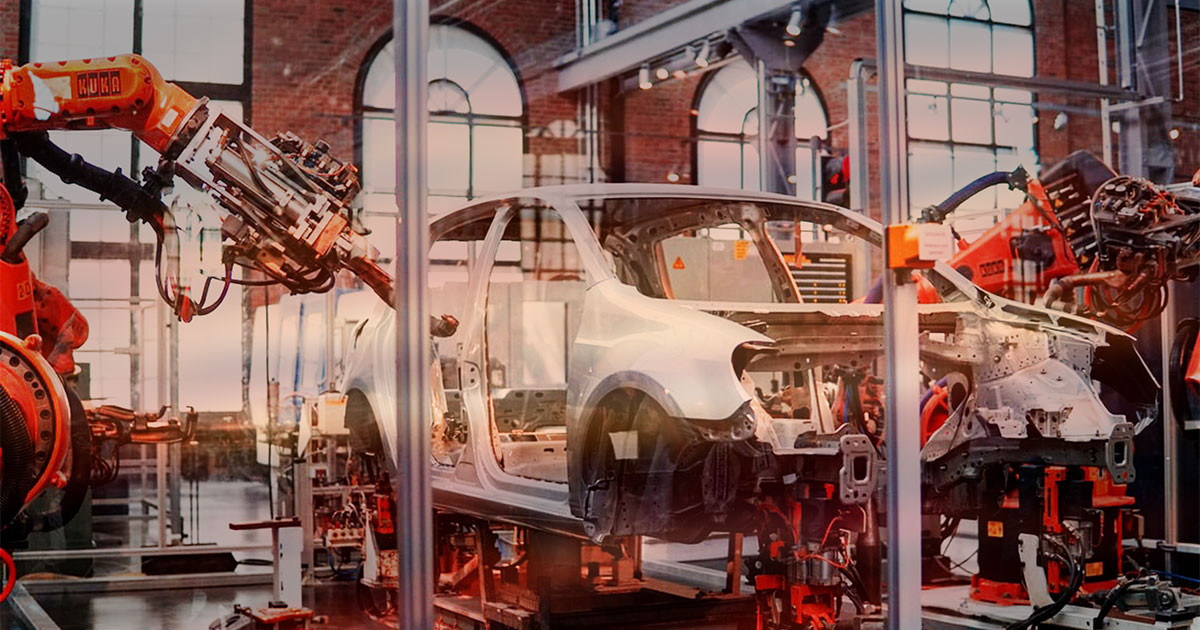

The Modern Manufacturer and the Smart Factory

As technology has changed at a rapid pace, so has manufacturing. Only twenty years ago, practically nothing had internet access. Now, it is hard to find something without internet access. A common way to explain how the manufacturing sector has changed is by referencing the steps of technological advancement that the manufacturing industry has taken.

The term OEE stands for Overall Equipment Effectiveness.

Have you ever heard about OEE? Many times, right? It sounds like a buzz word for a quality team. Overall Equipment Effectiveness is a standard metric for measuring manufacturing productivity for products or services. Whether you’re running a small or large business, implementing Overall Equipment Effectiveness is highly important.

IoT Challenges Debunked

Some of the most commonly discussed IoT challenges that prevent implementation are the financial investment risk and legacy infrastructure. From a financial standpoint, the investment may vary drastically depending on the number of IoT devices connected and platform used.

Top 10 Benefits of IoT for Manufacturers

IoT in Manufacturing is on the rise in record numbers. The global IoT market will grow from $321B in 2022 to $1.69T by 2030, attaining a Compound Annual Growth Rate (CAGR) of 23.1%. IoT in manufacturing has become the prelude to which many believe will be the 4th industrial revolution or as it is commonly been referred to, Industry 4.0.

Happy IoT Day From FREEDOM!

April 9th is IoT Day and is a great opportunity to learn more about the Internet of Things and what it means for all of us. As manufacturers, the networking capability that allows information to be sent between different objects and devices using the Internet can help organizations increase performance, productivity, and profitability.